Some of the sectors we serve

- As FSA Alfa Energy, we are known for our indigenised, national products and solutions we provide to the iron and steel industry. We carry out our productions with thermal and mechanical calculations and high engineering approaches.

- We expand our product range and support the national economy with the services we provide to the sector in terms of localisation.

- As Fsa Alfa Enerj, we design our products in accordance with your processes for the utilisation of waste heat and offer efficient and optimum solutions. Thanks to our products, we reduce your energy costs, increase your production performances and maximise efficiency.

- As Fsa Alfa Enerji, we offer products to the machinery sector with thermal and mechanical calculations and verified performances. We support the sector with more compact and efficient productions with our innovative and competitive designs in accordance with the needs of the sector.

- As FSA Alfa Energy, we produce products for the biomass sector that are resistant to high temperatures and pressures and comply with pressure vessels directives. We produce efficient and highly engineered solutions with our sustainable and environmentally friendly designs in the biomass sector. With our products such as boilers, waste heat boilers and economisers, we convert your waste energy into steam and hot water and carry your energy efficiency to the upper segment.

- As FSA Alfa Energy, we produce products resistant to high temperatures and pressures in the petrochemical sector and in accordance with pressure vessels directives. We produce efficient and highly engineered solutions with our products such as heat exchangers, evaporators and condensers in the petrochemical sector.

- As Fsa Alfa Enerji, we offer compact, efficient, long-lasting products to the textile industry with innovative and highly engineered solutions with thermal and mechanical calculations. We continue our support with spare parts support and solution-oriented approaches to questions.

- As Fsa Alfa Energy, we offer products with thermal and mechanical calculations, compact and innovative approaches to the maritime sector. Considering the needs of the sector, we produce competitive and innovative solutions with our products such as radiators, heat exchangers, economisers, waste heat boilers, condensers and evaporators that are resistant to sea water, easy to clean and modular.

- As Fsa Alfa Energy, we offer products to the food sector with thermal and mechanical calculations, compact and innovative approaches. Considering the needs of the sector, we produce competitive and innovative solutions with our products such as radiators, heat exchangers, economisers, waste heat boilers, condensers, evaporators in accordance with food regulations, easy to clean and modular structure.

We certify our designs and productions according to EN 13445, EN 12952, EN 12953, API 661, API 650 standards.

Our WPS and WPQRs have been completed for all welding methods we use in the processes and all of our welders working in the process are certified in SMAW, TIG and MIG-MAG welding methods according to TS EN ISO 9606-1 standard.

With our heat exchangers and energy recovery system designs and productions, we serve petro-chemical, iron and steel, automotive, natural gas, petroleum, textile, machinery, food, maritime, chemical, health, paper, hydroelectric and thermal power plants, leather and air conditioning sectors.

With our expanding experienced staff, we contribute to the national economy by exporting to European, Asian and African countries beyond our country borders.

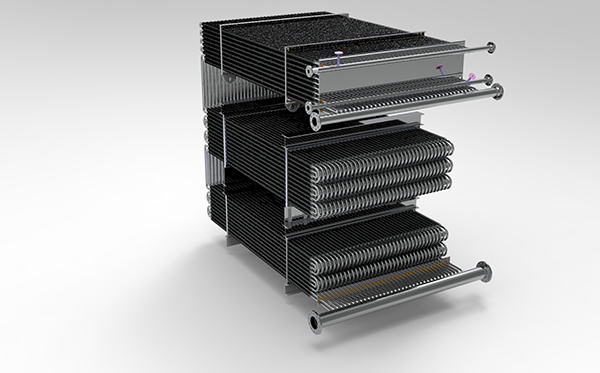

Finned Tube

- Serpentines consist of thin fins wrapped on pipes to increase the heat transfer surface area. Serpantines play an effective role in providing heat transfer. The fins are wound in certain thickness, height and pitch according to the pipe diameter and heat transfer surface requirement determined as a result of thermodynamic and mechanical calculations. Spiral wound coils are wound on flat and oval pipes as spot or continuously welded.

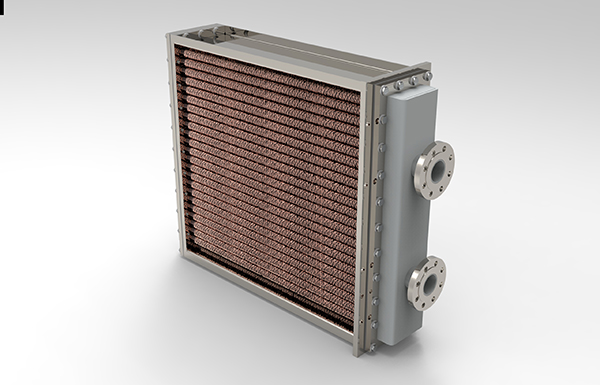

Radiator

- Radiators are formed by grouping serpentines. Radiators vary according to fluid types and places of use. According to fluid types, they are classified as hot water radiator, hot water radiator, sea water radiator, steam radiator, hot oil radiator. According to the type of serpentine, it can be classified as bare tube without wing, serpentine winding on straight pipe, wing arranged on oval pipe, wing arranged on straight double pipe, grooved and crochet pipe radiators.

Shell & Tube Heat Exchanger

- Heat exchangers are used to change the temperature of the existing liquid or gas fluid with another liquid or gas fluid. In heat exchangers, two fluids do not come into contact with each other. Heat exchangers are classified according to their fluids as water-water, water-oil, water-gas (air, nitrogen, etc.), steam-water, steam-oil, steam-gas (air, nitrogen, etc.), oil-oil, oil-gas, (air, nitrogen, etc.) heat exchangers. According to the production process, usage areas and pipe bundle structure, they are classified as straight tube and U-tube heat exchangers.

Economizer

- Today’s competitive conditions have led companies to conserve the energy, which has a high cost, at the highest level. Especially the utilisation of waste flue gas generated in steam, water and hot oil boilers and waste hot water energies in the textile sector has a great contribution to production costs and the national economy. The systems made by taking into account the process values pay for themselves in a short time.

Recuperator

- Today’s competitive conditions have led companies to conserve the energy, which has a high cost, at the highest level. Especially the utilisation of waste flue gas generated in steam, water and hot oil boilers and waste hot water energies in the textile sector has a great contribution to production costs and the national economy. The systems made by considering the process values pay for themselves in a short time.

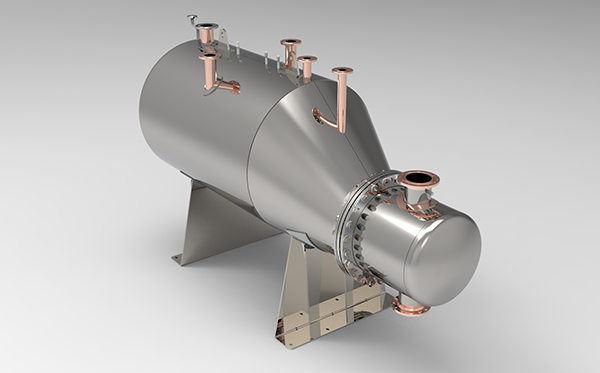

Waste Heat Boiler

Waste Heat Boiler is a heat exchanger that increases energy efficiency by recovering waste heat generated in a process. By utilising the heat in the waste gases, it creates a secondary energy source and stores this energy for use in another process. In this way, it minimises the impact on the environment by saving energy.

Pressure Vessels

Pressure Vessels are closed containers designed to operate under a certain pressure. These vessels are used to store, transport or process liquids or gases. Pressure vessels are manufactured in accordance with safety and engineering standards and often play an important role in industrial plants, power generation plants and chemical processes.

Special Productions

- We manufacture specific heat exchangers according to the pressure vessel directives with product compactness and optimum solution-oriented design in accordance with customer processes.

Why Choose Us?

Sector Expertise: We offer customised solutions by understanding the complex processes and requirements in the petro-chemical industry.

Innovative Designs: With the latest technology and innovative designs, we improve the efficiency and performance of your plants.

Durability and Reliability: Our products are designed to withstand harsh operating conditions and are focused on reliability.

Quality Standards: By manufacturing in accordance with international quality standards, we offer reliable and long-lasting products.

As FSA Alfa Energy, we offer the best solutions to those who want excellent performance and reliability in the petro-chemical sector. You can also rely on us to increase the efficiency of your facilities and save energy.

With our staff, solution partners and customers, we are a big family.